Centrifugal Concentrator

Centrifugal Concentrator

>> Ore discharge automatic, discharge fast.

>> High concentrating ratio and high recovery

>> Total process automation, steady recovery performance

>> Low water and electricity requirements

>> Low production costs, durable wear parts, minimal maintennance requirements

>> Compact design requiring less space, easy merged into the existing mining processing

Description of centrifugal concentrator

The centrifugal concentrator is a new type of gravity separation equipment which is designed for gold, silver, tin, lead and other precious metals. The centrifugal concentrator achieves the mineral separation by making use of the differences of minerals density under the conditionof high speed centrifugal rotating, force recoil pressure water. Proved by experiment, the separation result is very significant for gold ore. The recovery rate reach more than 95% for the individual gold above 300 mesh, enrichment ratio is up to 1000 times. It can completely replace the function of fixed chute, spiral chute, jig, etc gravity equipment in the mineral process, also solve the problem efficient of fine gold run into the tailing for traditional chute.

Working Principle of centrifugal concentrator

The Centrifugal concentrator utilizes the principles of centrifuge to enhance the gravitational force experienced by feed particles, which aids in the separation process based on particle density. The key components of the unit include: a cone shaped "concentrate" bowl, which is rotated at high speed by an electric motor and a pressurized water jacket encompasses the bowl. Feed material, typically from a ball mill discharge or cyclone underflow bleed, is fed as a slurry toward the center of the bowl from above. The feed slurry contacts the base plate of the vessel and, due to its rotation, is thrust outward. The outer extremities of the concentrated bowl house a series of ribs, and between each pair of ribs is a groove. During operation the lighter material flows upward over the grooves and the heavy mineral particles (usually of economic value) becomes trapped within them.

Features of centrifugal concentrator

The centrifugal automatic ore discharge system is developed by our company due to the disadvantages of machine start-up, complicated operation of discharge ore by stop machine, waste manual work for the old model, fully realize the automatic operation. A button can realize all the works.

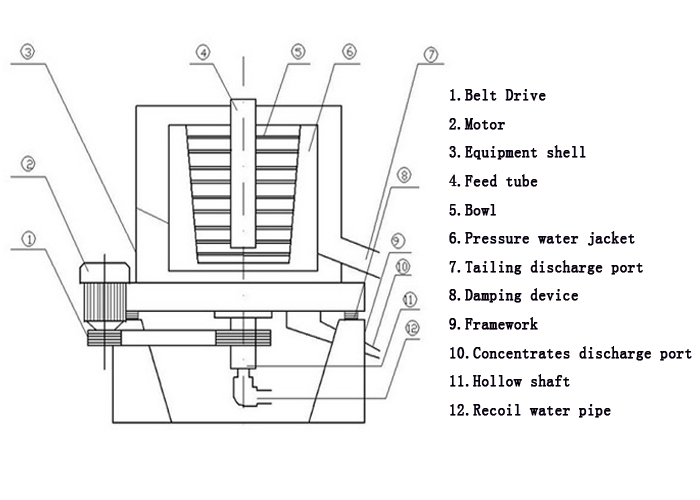

Structure

of centrifugal concentrator

Technical Specification of centrifugal concentrator

of centrifugal concentrator

|

Model |

STLB20 |

STLB30 |

STLB60 |

STLB80 |

STLB100 |

|

Capacity (T/H) |

1-3 |

2-7 |

15-30 |

30-70 |

60-100 |

|

Feeding size (mm) |

0-3 |

0-3 |

0-5 |

0-5 |

0-6 |

|

Feeding density |

<50% |

<50% |

<50% |

<50% |

<50% |

|

Fluidization water (m³/H) |

1-2 |

4-6 |

10-20 |

20-35 |

40-60 |

|

Concentrates weight (kg) |

2-3 |

8-15 |

25-40 |

60-70 |

70-80 |

|

Water pressure (Mpa) |

0.06-0.1 |

0.1-0.15 |

0.1-0.2 |

0.1-0.2 |

0.1-0.2 |

|

Motor power(kw) |

0.75 |

1.5 |

4 |

11 |

18.5 |

|

Dimension(mm) |

800×700×980 |

1050×900×1150 |

1600×1400×1800 |

2100×1800 ×2100 |

2300×2000 ×2200 |

|

Weight (kg) |

270 |

420 |

1600 |

2500 |

3750 |

Application of centrifugal concentrator

Contact Us

|

Contact person:Dana Lai

|

|

Tel:+86-15970772921

|

|

|

Fax:+86-797-5793558

|

|

|

Email:jinshibaomachine@shakingtable.com.cn

|

|

|

Skype: firon1818

|

|

|

Website:www.shakingtable.com.cn |

- Previous:Spiral Chute

- Next:JT Jig Machine