Ball Mill

MQG Ball Mill

>> High efficiency and low invest with high return

>> Even product size that means the shape of the final products is circular

>> Easy operation and easy maintenance

>> Good stability and low energy consumption

>> Adjustable device

>> No pollution and low noise

Description

The ball mills Jinshibao manufactured are mainly the wet type ball mill which is widely applied for wet grinding in indrustries of beneficiation, chemicals, constructions, and so on.

There are 2 kinds of ball mill, grate type and overflow type due to different ways of discharging. The grate type ball mill is devided into short cylindrical ball mill which is suitable for coarse grinding, and long cylindrical ball mill which is suitable for fine grinding. The overflow type ball mill is always used in the secondary grinding, while the grate type is always used in the first grinding, forming the closed-circuit with the spiral classifier.

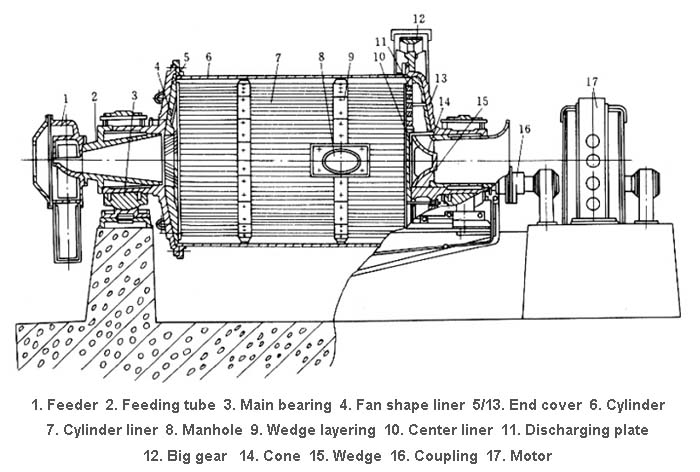

Structure

Working Principle

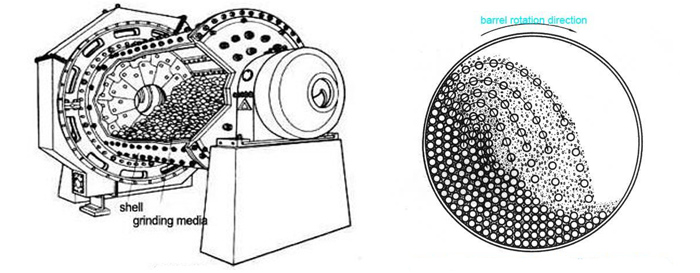

Ball mill is a horizontal rotating device transmitted by the outer gear. Materials are transferred to the grinding chamber through the quill shaft uniformly.

There are ladder liner, ripple liner and different specifications of steel balls in the chamber.

The centrifugal force caused by rotation of cylinder brings the steel balls to a certain height then impact and grind the materials.

The ground materials are discharged through the discharging board thus the grinding process is finished.

Technical Specification

| Model |

Diameter (mm) |

Length (mm) |

Max.feeding size(mm) |

Output size (mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

| MQG0918 | 900 | 1800 | 20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| MQG0930 | 900 | 3000 | 20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| MQG1224 | 1200 | 2400 | 25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| MQG1230 | 1200 | 3000 | 25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| MQG1245 | 1200 | 4500 | 25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| MQG1530 | 1500 | 3000 | 25 | 0.074-0.4 | 2.0-5.0 | 75 | 15.6 |

| MQG1545 | 1500 | 4500 | 25 | 0.074-0.4 | 3.0-6.0 | 110 | 21 |

| MQG1557 | 1500 | 5700 | 25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| MQG1830 | 1830 | 3000 | 25 | 0.074-0.4 | 4.0-10 | 130 | 28 |

| MQG2130 | 2100 | 3000 | 25 | 0.074-0.4 | 6.5-36 | 155 |

34 |

The above models are only some of the standard model sizes. The ball mill can be custom-made as per your ore information.

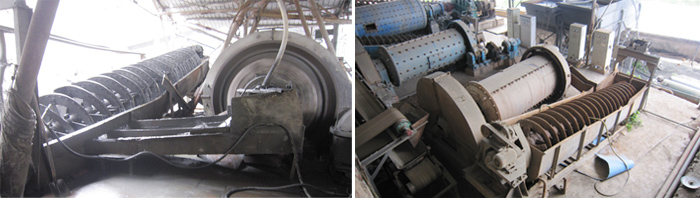

Application

The ball mill is usually applied together with the spiral classifier or hydrocyclone to form a closed-circuit during which the minerals which do not reach the separation particle size could be sent back to the ball mill for re-grinding.

Contact Us

|

Name: Sabrina Huang

|

|

Skype: sabrina88196

|

|

|

Tel: 0086-15879777833

|

|

|

Email: jinshibaosabrina@shakingtable.com.cn |

- Previous:Wet Pan Mill

- Next:Hammer Mill